This beautiful old Gibson was a little worse for wear when it entered the shop. The bridge was lifting from the top and the pitting in the first four frets rendered it unplayable in root position, in addition to the tuners being deteriorated. Bringing back old instruments with a complete overhaul are the type of jobs we love here at Straight Frets though!

Notice the large gap between the bridge and the soundboard. Even the old nylon strings this guitar was wearing were giving it difficulty. The bridge will have to be removed completely and reattached for this guitar to sound like it should.

After a little heat is applied to loosen the glue, a sharp putty knife is used to get under the bridge and remove it. These old Gibsons are hiding screws underneath those pearloid dots, which have to be unbolted from the inside. Also notice the glue in the saddle slot. It was tricky to remove the saddle in one piece. All that glue will have to be removed too as it eats up the sound of the guitar.

The two gluing surfaces will have to be cleaned up to get a strong joint.

A curved Schneider glue clearing chisel is intended for cleaning glue around braces, but it’s also cut out for this job. What a great chisel! A new sharp micro chisel gets the hide glue out of that saddle slot. We also used the new Stew-Mac saddle slot files to get a nice flat slot for maxium contact to the bone saddle.

With both surfaces cleaned up, we can glue it back on with bridge clamps.

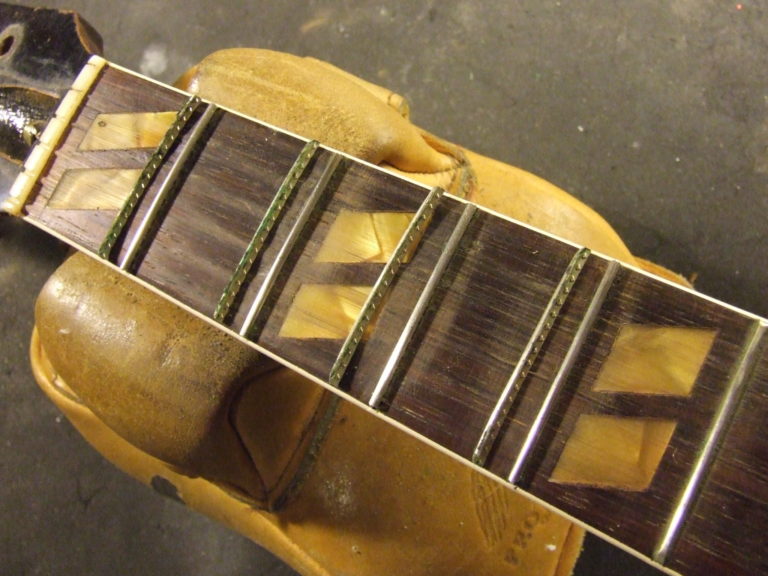

With the bridge taken care of, it’s time to replace the first four frets. The pitting here is almost down to the wood.

We tried a bunch of sources to find the correct width fret wire to match the originals: Jescar, Dunlop, LMI, Stew-Mac, Hosco, and even Grizzly & eBay, but nobody makes it this size anymore. If anyone out there has any of this fret wire from yesteryear and is willing to part with some, please contact me and I’ll buy it!! In the end we had to file the new wire down to the correct size one peice at a time. It took a little extra time, but frets .013″ wider than the rest will be visible with the naked eye.

The new frets are sitting in their respected slots and are ready to be pressed in.

The frets are glued and pressed in individually, then clamped with a radius block until the titebond dries.

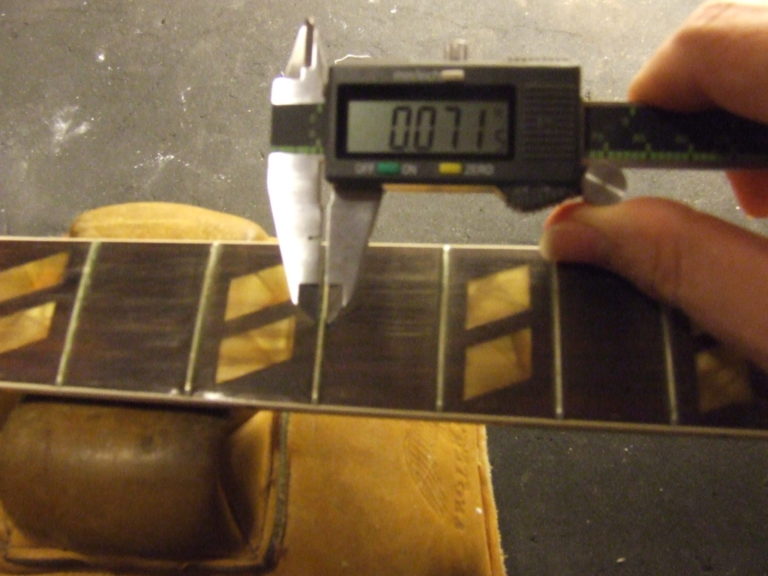

The Stew-Mac calipers have a handy feature which allows you to check the height of the old frets.

The new frets are leveled to match and polished to shine.

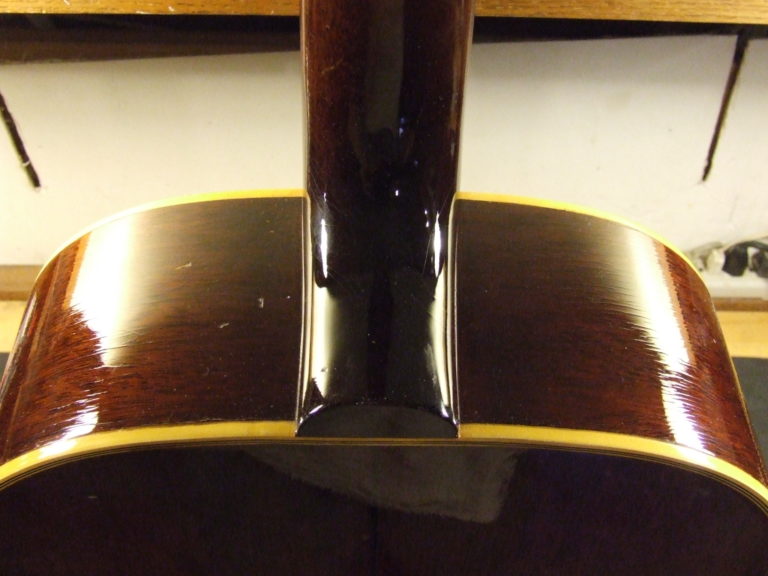

Frets and bridge completed, time to clean up the old finish at the buffing station.

The original tuners were sadly fried, so it’s time to put on some replacements.

We can use the original bushings, so we don’t have to remove any wood to make way for the new tuners. We polished them up to make them look like new with the metal polishing station and Menzerna metal polishing compound. These pliars are modified to hold circular objects like this securely for the metal buffing wheel.

The new tuners look great. This old J-45 will finally be able to hold a tune again.

50 years of smoke and grime lifted off the finish to give it a gloss once again. This guitar turned out very well indeed. Here’s to another 50 years!